Description

Century Woven Gabion Basket

Product

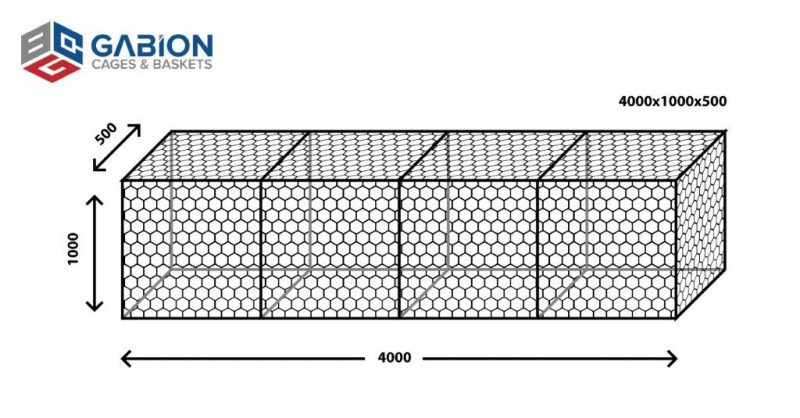

- Woven Gabion Basket 4000x1000x500

- Dimensions : 4000 x 1000 x 500

- Aperture Type : 80mm x 100mm

- Wire Diameter : 2.7mm

- Double Twisted

Optional Variation For Marine Applications

- PVC Coating (available via drop down box)

Key Features

- Industry Leading Wire Tensile Strength

- 4 x 1 metre spiral wire (4mm bezinal coating)

- International & Australian Standards Compliant ( EN 10244-2 : 2001)

- Suitable For Civil Projects

- Material / Coating Data Sheets Available Upon Request

- ISO 9001/2008 Quality Manufacturing

- Local Stock Holdings For Time Critical Projects

Gabion Basket Includes :

- 2 panels 4000×1000

- 2 panels 4000×500

- 5 x panels 1000×500

- Lacing wire / Selvedge Wire (4mm bezinal coating)

- Flat Packed Configuration

- * Optional C Rings

Century Gabion Applications

- Civil Construction, Commercial Landscape

- Free Standing Walls & Fences

- Retaining Wall Structures

- Erosion Control

- Civil Works

- Scour Protection

- Weir Structures

Century Gabion Specification Overview

Superior Corrosion Resistance

Bezinal® coated wires resist corrosion 2 to 6 times longer in heavily polluting corrosion tests than hot-dip galvanized wires and last up to 8 times longer in heavily polluted areas**. This is thanks to the formation of the dense and high quality passivation layer that is mainly formed by aluminum oxides.

** Based on salt spray tests and Kesternich tests

Cathodic Protection

Zinc-alloy coatings also offer cathodic protection of uncoated areas of the steel (e.g. cut-ends or scratches). The active coating generates an electrical current which reverses (counteracts) corrosive attack of the steel.

Heat Resistance

Regular hot-dip galvanized (HDG) wires tend to experience alloy layer growth when exposed to higher temperatures. This alloy layer is the interface between the metallic coating and the steel wire. It generally contains the elements of the top coating combined with iron from the wire core. However, coatings of the Bezinal® range are immune to this phenomenon due to an inhibiting action of aluminum.

Tried and Tested

To ensure the good quality and performance of our products, Bekaert constantly performs various standardized tests for product development or on the specific request of our customer. Bekaert performs corrosion tests from their own ISO 9001 certified laboratories and has them confirmed by various independent research facilities across the globe.

Reviews

There are no reviews yet.